A Guide To Leavers Lace

What Is Leavers Lace?

Leavers lace is among the most elegant lace available and is highly sought after, thanks to its beautiful and intricate details - the end result of a painstaking and skilful manufacturing process.

Photo by Stany Dederen

Photo by Stany Dederen

Shop Leavers Lace Lingerie

|

Empreinte Melody Collection

|

Shop Lise Charmel Collection

|

The Origins of Leavers Lace

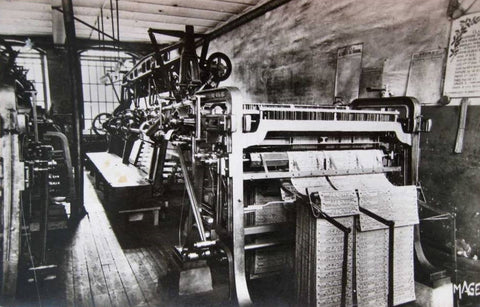

In 1813 John Levers, a framesmith from the Nottingham market town of Sutton-in-Ashfield, modified a pre-existing ‘Old Loughborough’ lace-making machine that had been created by John Heathcoat. The Leavers machine (the ‘a’ was added to ‘Levers’ after about 100 years, and the spelling was subsequently standardised that way) is used to make intricate patterned lace.

Photo by Clem Rutter

Photo by Clem Rutter

With very few leavers machines still around, the lace is considered to be a work of art.

Leavers Lace Machines

Photo by Jannick Jeremy

Photo by Jannick Jeremy

The original machines were big, noisy, ungainly machines, which seems at odds with the delicate nature of the lacework they produce. The machines were made to create garments that matched the quality of handmade lace. While the machine does the actual weaving, many skilled people are still required in the production of Leavers lace.

How is Leavers Lace Created?

Designs can take weeks to produce, and the lace is expensive to manufacture.

The designs are drawn on paper and then translated into punch cards, which are fed into the loom to create the pattern. Thousands of individual threads are loaded by hand and woven together to create leavers lace. The more detail in the design, the more threads are needed, so the increase in complexity of design raises the price of the finished garments.

There is a lengthy process with many steps to create this delicate lace, each one requiring an expert with their own specialism:

- The process begins with the drafter, whose job is to draw up the initial design for the lace pattern.

- This design is then passed to the technical drafter. Their role is to transpose that drawing into a tracing.

- The lacemaker has responsibility for setting up the carriages and threads. It is important that every yarn is in exactly the right position.

- The winder’s job is to place each thread on bobbins and prepare the strands to weave the lace. Each bobbin is placed into a carriage and checked to make sure weight and tension is correct.

- It is then up to the inspector to look for the tiniest defect in the motif.

- The machine is then set to run, and creates the design line by line. Workers must keep the machine fed with more thread as the process continues.

- Loom experts, called tullists, oversee the whole operation and make sure the design is being created on the loom.

- Once the machine has finished creating the design, the lace inspector or mender fixes any errors, which are all done by hand. Their job is to ensure any repairs exactly match the rest of the lace.

- The process ends with the colourist and in-house designer who add personality to the piece.

Photo by Clem Rutter

Photo by Clem Rutter

The finished Leavers lace is used in numerous ways, such as for clothing, lingerie and embroidery.

Why Is Leavers Lace Different From Other Lace?

Unlike other types of lace, Leavers lace is not produced by automation and the designs aren’t embroidered onto the top of fabric. The whole piece is woven, which creates intricately detailed and beautiful material.

As you can see from the description of the processes, equipment and craftspeople involved, Leavers lace is a highly specialised product that needs skill, knowledge and time, plus specific, rare machinery to be created. It is a work of passion, not a mass-produced product.

Photo by Stany Dederen

Photo by Stany Dederen

Leavers Lace in Nottingham

It’s fair to say that lace put Nottingham on the map back in the 1800s. The lace industry in the region reached its zenith in the 1890s when it employed over 25,000 people. The Lace Market is a historic quarter-mile square area of Nottingham. This was the hub of the world's lace industry during the British Empire, and is now a protected heritage area.

In 1897, Nottingham was granted the status of city by Queen Victoria. At that point it was a major area for lace production, exporting its products all over the world.

Although the great industrial production of lace in Nottingham has largely come to an end as economic changes and modernisation have seen the industry move elsewhere, Nottingham still has many craftspeople who work in lace.

French Leavers Lace Lingerie

Most Leavers lace is now made in France, particularly in the region of Calais (so much so that designers refer to Leavers lace as 'Dentelle de Calais'). It maintains the same high standards and is extremely fine and delicate, often with complex patterns.

'Chantilly' lace, where the pattern is interrupted throughout the design and surrounded by tulle, is a type of Leavers lace that requires threads to be clipped by hand around the start and finish of each new lace design. This type of lace is often used in high-end luxury lingerie.

One of the designers that we showcase at Caroline Randell is Marjolaine - an exquisite French nightwear brand, made from 100% silk and richly adorned with French Leavers lace.

Marjolaine's designer, Carole Guerin, is an imaginative and innovative creative, crafting beautiful camisoles, babydolls, negligees, nightdresses and chemises, using original fabrics and hand-cut Calais lace, in a subtle blend of creativity and femininity.

The pearl silk chemise is a superb example of a garment featuring Leavers lace, showcasing the level of attention to detail that creates such wonderful nightwear. It has beautiful white Leavers lace inlays on delicate satin silk. The plunge lace neckline and hem are intricate, seductive and beautifully woven.

Leavers Lace Price - Is It Expensive?

Photo by Stany Dederen

Photo by Stany Dederen

Leavers lace can be up to ten times more expensive than other types of lace due to the personnel, specialist expertise, rare and expensive machinery and the overall lengthy process needed to create the final product. However, the intricacy of the designs, delicacy and attention to detail that goes into the final product makes it more than worth the extra investment.